GYPSUM

Gypsum powder (Calcium sulfate Dihydrate/ Hydrous Calcium Sulfate) is a smooth white powder derived by heating Gypsum stone. The Gypsum that is mined is heat dried, crushed and ground into a powder. This powder has numerous applications in industry and construction.

Gypsum has always been reputed to be a leading building material worldwide. It was used by many ancient civilizations like ancient Egyptians who built their pyramids using mortars of gypsum. The importance of gypsum powder has been rising ever since. This is because state of art technology enables gypsum and gypsum-based products to feature more mechanical and physical properties such as durability and longevity.

The superior quality of gypsum in making construction materials is because of its qualities of aesthetics and comfort. This material is commonly available, natural and odorless. It also has a natural mechanism to create a balance between humidity and climate of indoors.Gypsum plaster provides matchless, smooth white surface free of scars and cavities. Gypsum products are also good for indoor finishes. They are environment-friendly, fire resistant and provide acoustic and thermal insulation. They are also good for human health.

USAGE OF GYPSUM POWDER

Nearly all modern homes and buildings use gypsum in the form of wall board, also known as gypsum board, drywall or sheet rock. Homes in some countries typically contain tons of gypsum in the form of drywall. It is attached to wooden framing to make walls and ceilings. Gypsum powder mixed with water becomes hardened and rock-like when dried. The hardened gypsum is pressed between sheets of paper to form slabs of drywall. Drywall makes an inexpensive building material that can easily be cut to size. It provides a sound barrier and is resistant to fire.

Gypsum powder is also added to cement and paints used in building construction and finishing. In cement and concrete mixes, gypsum helps to increase the time it takes for concrete and cement to dry and harden, resulting in a more stable structure. In paint, gypsum powder is used a filler to adhere to the pigments and improve the paint’s texture.

Gypsum powder is used in agriculture as a soil conditioner and fertilizer. Applying it to soil as a fertilizer contributes calcium and sulfur, two nutrients used by plants. Gypsum powder is especially beneficial to corn and soybeans, which need a lot of sulfate in the soil to thrive.

Because gypsum is considered generally safe for humans, it can be used in small amounts in food and beverage production. In the food industry, gypsum may be used as an anti-caking agent, drying agent, dough-strengthener, firming agent, color enhancer, stabilizer and thickener. Food products that may be made with gypsum include baked goods, frosting, candies, ice cream and other frozen dairy products, puddings, gelatins and pasta. Gypsum powder is also a non-active ingredient in toothpaste.

IRAN’S GYPSUM POWDER EXPORT

Historically, Iran has exported around 10% of its total annual gypsum production, with the balance consumed by local cement, gypsum and construction industries. The gypsum production cost plays a major role in the Iranian gypsum industry and the profitability of gypsum production in Iran has decreased in recent years due to low FOB selling prices.

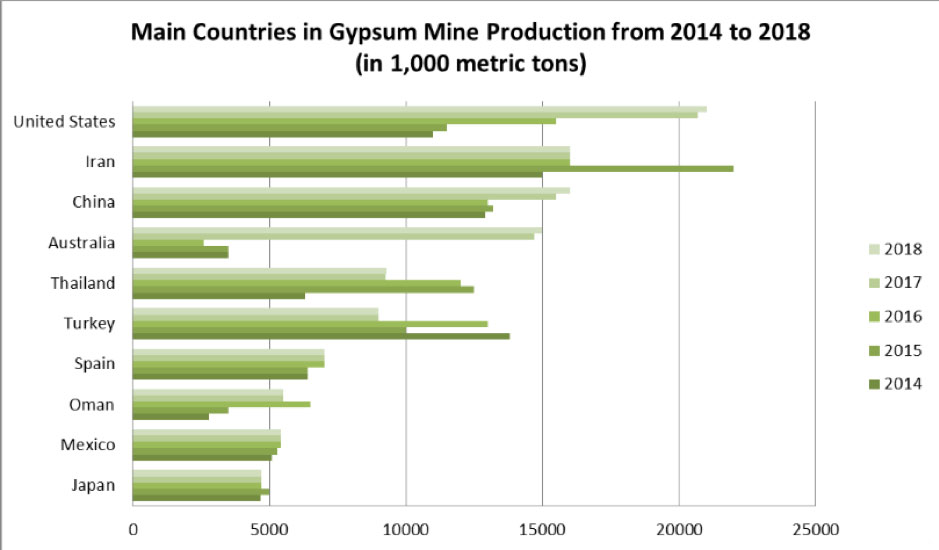

The name of Iran is always shining in gypsum production as well as exporting it to various countries. In 2018, gypsum production of Iran amounted to approximately 16 million MT. Therefore, Iran is the second country in gypsum mine production globally. Iran’s gypsum production was 15,000 million MT in 2014 which rapidly jumped to 22,000 million MT in 2015 and then fell to 16,000 million MT in 2016. ( Source :Financial Tribute) Iran exports mainly to UAE, Qatar, Kuwait, Indiaand a few other Asian countries.

INDIA IS THE LARGEST IMPORTER OF GYPSUM

Indian cement and gypsum wallboard industries will require more than 280Mt of gypsum in the 15 year period to 2030 due to the country’s limited domestic supplies. This has been calculated using year-on-year growth rate of 8%. There are large but non-viable natural reserves in Rajasthan. India also makes around 6Mt/yr of byproduct phosphor-gypsum as a result of fertiliser production. However this will not increase greatly due to issues surrounding the supply of diammonium phosphate.