Polystyrene

Polystyrene is a versatile plastic used to make a wide variety of consumer products. As a hard, solid plastic, it is often used in products that require clarity, such as food packaging and laboratory ware. When combined with various colorants, additives or other plastics, polystyrene is used to make appliances, electronics, automobile parts, toys, gardening pots and equipment and more.

General Purpose Polystyrene or GPPS

A transparent polymer and style appropriate to maintain the appearance and electrical properties is highly desirable. Transparency and ease of processing this material because of its amorphous structure, benefits are high compared to other polymeric materials. This type of polystyrene used in the manufacture of containers such as plates, glasses and cups, high strength, as well as household utensils and cans of consumer goods, especially goods packaging such as boxes and frames CD thin and delicate, packaging materials and machinery. Also, due to the dielectric properties of the material, it can also be used in electrical applications

High-Impact Polystyrene or HIPS

Conventional polystyrene somewhat fragile, although we can add some properties of materials such as poly-butadiene, to obtain a product with optimal performance. This material is due to the influence of intermolecular forces, normally cannot be mixed together.

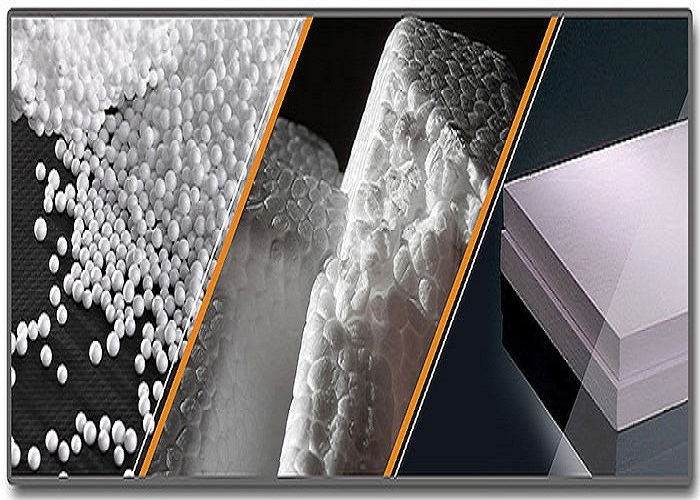

Expanded polystyrene or EPS

Thermoplastic is a style that low thermal conductivity, high resistance and high ability to absorb impact , make it an ideal material for packaging and insulation in different industries has made. It is known in Iran as the polystyrene.

Extruded Polystyrene - XPS

A type of plastic that is used to manufacture a wide range of products, from construction materials to storage containers, used according to its users, it is possible to form a dense foam material or an incompressible solid product produced.

Polystyrene Uses in Our Daily Life

Iran export of Polystyrene

Refrigerators, air conditioners, ovens, microwaves, vacuum cleaners, blenders – these and other appliances often are made with polystyrene (solid and foam) because it is inert (doesn’t react with other materials), cost-effective and long-lasting.

Polystyrene (solid and foam) is used to make many car parts, including knobs, instrument panels, trim, energy absorbing door panels and sound dampening foam. Foam polystyrene also is widely used in child protective seats.

Polystyrene is used for the housing and other parts for televisions, computers and all types of IT equipment, where the combination of form, function and aesthetics are essential.

Polystyrene foodservice packaging typically insulates better, keeps food fresher longer and costs less than alternatives.

Lightweight polystyrene foam provides excellent thermal insulation in numerous applications, such as building walls and roofing, refrigerators and freezers, and industrial cold storage facilities. Polystyrene insulation is inert, durable and resistant to water damage.

Due to its clarity and ease of sterilization, polystyrene is used for a wide range of medical applications, including tissue culture trays, test tubes, petri dishes, diagnostic components, housings for test kits and medical devices.

Polystyrene (solid and foam) is widely used to protect consumer products. CD and DVD cases, foam packaging peanuts for shipping, food packaging, meat/poultry trays and egg cartons typically are made with polystyrene to protect against damage or spoilage.